Hi kids, today we’ll talk about the RBMK’s counterpart, the VVER reactor.

VVER and its history

The Water-Water Power Reactor (Водо-водяной энергетический реактор, VVER for short), was a Pressurized Water Reactor (PWR), using light water both as the coolant and the moderator. It was first developed in the 1950s in the Soviet Union as a parallel track to the RBMK. Unlike the RBMK, which was for domestic use and for also producing plutonium, the VVER was the Soviet’s “Western style” reactor, comparable to US PWRs and French PWRs.

The earliest VVERs were built before 1970, with the VVER-440 Model V230 being the most common design, capable of delivering 440MW of electrical power. Such model was equipped with 6 coolant loops, each powered by a horizontal steam generator. Later on, with new Soviet nuclear safety standards, the VVER-440 Model C213 was adopted. This model added ECCS (Emergency Core Cooling System) and auxiliary feedwater systems, along with upgraded accident localization systems.

In 1975, the much more powerful VVER-1000 was developed, with a 4-loop system inside a western-style containment-type structure equipped with ECCS. Currently, Rosatom offers the VVER-1200 up for construction, and is currently constructing their first ever VVER-1300 (VVER-TOI) unit.

Key Generations:

VVER-210 / 365 / 440 (1960s-70s): First generation, exported widely.

VVER-1000 (1970s – 80s): Higher power, major export design.

VVER-1200 (AES-2006) (2000s): Gen III+, equipped wth passive safety systems.

VVER-1300 (VVER-TOI): Advanced reactor meant for standardized, modular construction.

How the VVER works

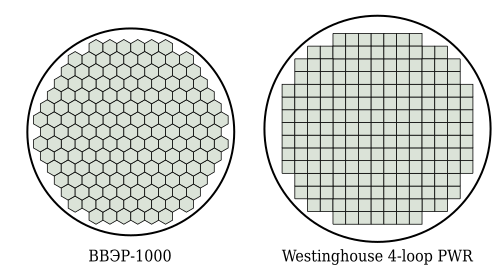

As mentioned, the VVER is the Soviet flavor of a PWR. Unlike RBMKs, which use unenriched Uranium, the VVER uses enriched uranium dioxide (~3-5% U-235), and fuel rods are bundled into assemblies shaped like a hexagon and placed into the core. Additionally, the VVER uses light water as both its coolant and moderator, even though the RBMK uses graphite as its moderator and light water as its coolant.

^ This image shows the side-by-side comparison of the fuel assemblies VVER-1000 and Westinghouse’s PWR. There are 163 such assemblies on the VVER and 193 on the Westinghouse design.

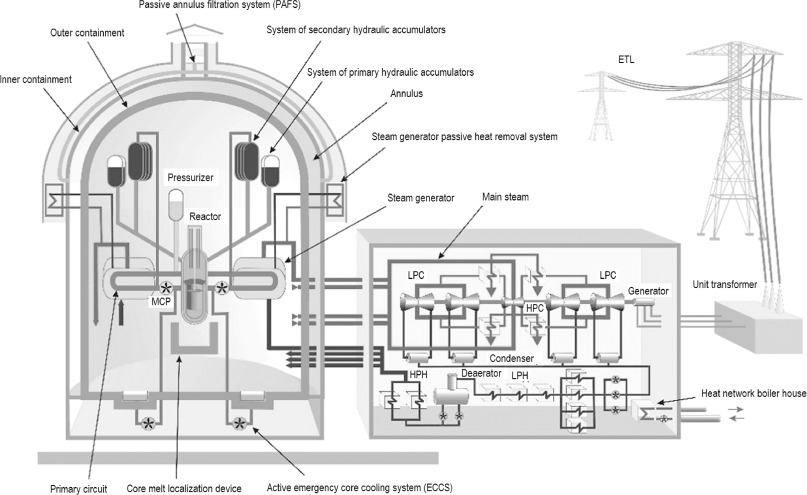

Like a normal western PWR, the water in the core is kept under high pressure (~15-16 MPa) so that it does not boil. Such water will travel through the primary circuit and is pumped into steam generators, where the primary water will heat up another separate secondary water loop, turning it into steam, driving the turbines to produce electricity.

Unlike RBMKs, the VVERs have steel-reinforced concrete containment domes. Modern VVERs use negative void coefficients, meaning if water turns to steam, reactivity will drop (a self-stabilizing reaction). The RBMKs had a dangerous positive void coefficient, which played a key role in the 1986 Chernobyl disaster.

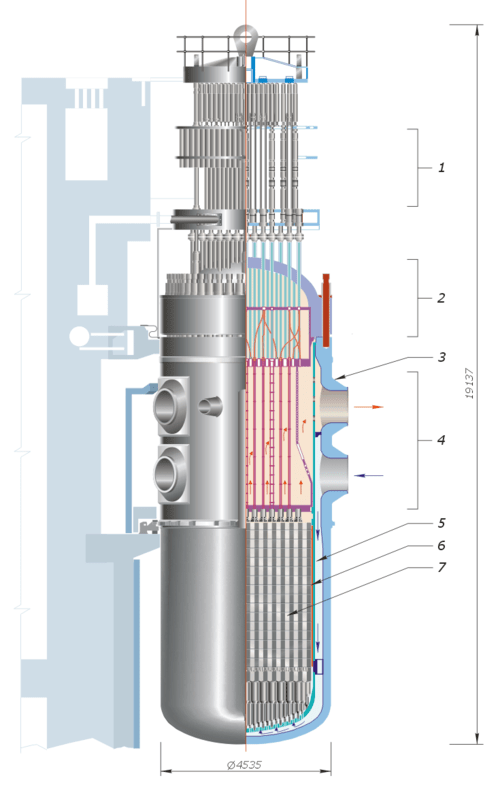

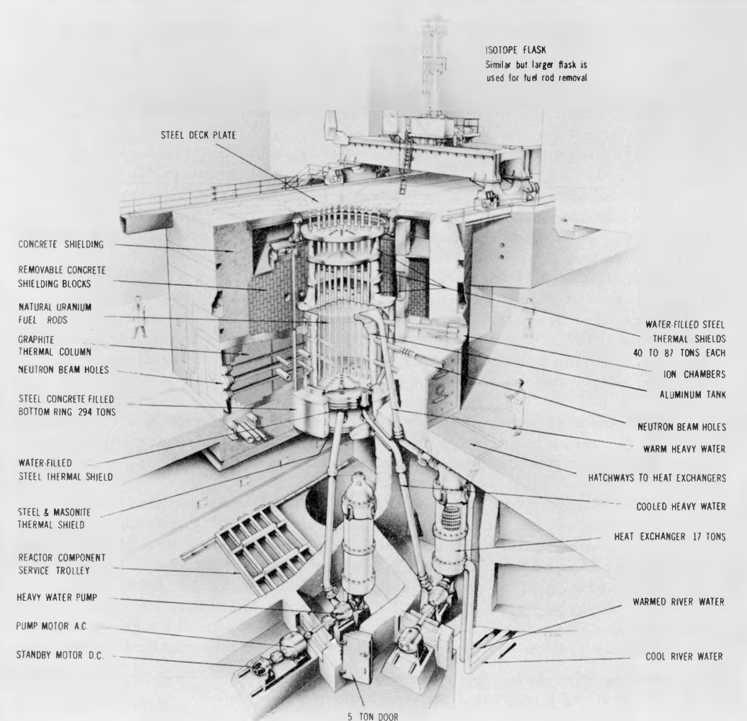

^ The VVER-1000 reactor. Keys are as follows:

1: control rod drives

2: reactor cover or vessel head

3: Reactor pressure vessel

4: inlet and outlet nozzles

5: reactor core barrel or core shroud

6: reactor core

7: fuel rods

The VVER-1200 and its difference to the RBMK-1000

Now, let’s talk about the most modern VVER reactor that has been built, the VVER-1200. The VVER-1200 is a Generation III+ PWR, capable of generating up to 1200MW electrical (3200 MW thermal), and is capable for approximately 60 years of service. The reactor features a V-392M watre-cooled thermal neutron reactor, four horizontol type PGV-1000MKP steam generators, A K-1200-6.8/50 turbine installation with one high-pressure cylinder and four low-pressure cylinders, and a single T3B-1200-2A type turbine generator.

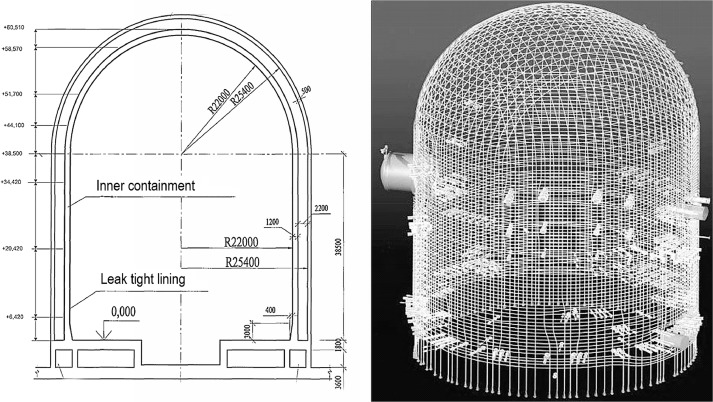

The VVER-1200 features a double containment system, which means the reactor building has two seperate, leak-tight barriers around the reactor core and primary systems instead of just one.

The Inner containment (primary) is made of pre-stressed or reinforced concrete with a steel liner. Such containemtn is designed to withstand high internal presssure like steam release, and prevents radiactive materials from escaping into the environment. The outer containment (secondary) protects against external impacts such as aircraft crashes and earthquakes. It also acts as an extra barrier incase the primary one fails. The Annulus Space (between the two walls) is monitored and kept under slight negative pressure. This will ensure that if the inner containment leaks, air will flow inward rather than allowing radiactive waste to escape outward.

The VVER-1200 also features multiple passive safety systems, in contrast to the RBMK-1000. The RBMK-1000 relied on active systems (pumps, operator actions). If power was lost, safety features could fail. However, the VVER-1200 has passive heat removal systems, which works without electricity or operator intervention. Additonally, a core catcher has been added, which is a device that traps and cools molten core material if a meltdown occurs.

The RBMK-1000’s control rods featured graphite displacers (for more information, read my post of “Understanding the design of the pre-Chernobyl RBMK-1000“), which initially increased reactivity when inserted, which caused the 1986 explosion in Chernobyl. Furthermore, the A3-5 (SCRAM) sequence of the RBMK was very slow (18 seconds) and it could even fail under some conditions, which certainly did not help along with the graphite displacers in the time of the accident. However, the VVER-1200 uses boron-enriched water and solid absorber rods, along with a fast and reliable SCRAM system.

The reasons for all these differences of the VVER and the RBMK is due to several factors. First, the RBMK-1000 was developed under Cold War secrecy, without much regard for international safety norms. However, the VVER was built towards IAEA standards, and made for international export unlike the RBMK.

that’s it for today, bye pookies.

Leave a comment